-

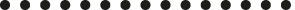

Mauro Saviola

More than just a successful entrepreneur, Mauro Saviola was above all a man who believed in his ideas and tenaciously pursued them until they bore fruit. It was a tale of passion and intuition, where expertise and chance were interwoven with a common thread of a boundless passion for wood.

-

The year it all started

The brothers Angelo and Mauro Saviola founded the company Sadepan in Viadana with Dino Del Ton, created for the manufacture of particleboard. The evening of 30th July 1963 the first Sadepan branded panel came off the production line. An agreement made with the Austrian company Hiag for the exclusive purchase of glue enabled Sadepan to survive the price war with its competitors, rendered all the more fierce by the monopolistic prices imposed by multinational glue manufacturers.

-

Melamine-faced panel

Fresh ideas, creativity and courage enabled Mauro to stay ahead of the game with regard to the needs of furniture manufacturers. It was a strongly expanding market that demanded a ready supply of semi-finished goods. With notable investments in research and development, the production of melamine-faced panel board began, with sales doubling.

-

Beyond wood, the chemicals

The plant started up for the production of formaldehyde and urea glues. Sadepan continued to challenge the massive chemical companies, making itself independent and establishing an integrated production system.

-

Melamine panel

Stone, marble, fabrics, but above all wood. The panel began to be coated in ways that opened up new aesthetic possibilities with decorative papers and finishes, offering real alternative uses for existing materials. These for us, “the New Originals”.

-

Mauro alone at the helm

These were the years of the creation of a number of factories, including the strategic premises at Mortara (PV), which has over the years become the factory par excellence of high added value melamine panels, and also of the acquisition of competitor companies. Saviola’s pioneering attitude was not readily accepted as it was a high risk strategy. So it was that in 1983 Mauro found himself alone at the helm. Free, unhindered and able to fully express his entrepreneurial spirt, he took Sadepan to the leadership of the Italian market as it became one of the top companies in Europe within its business sectors.

-

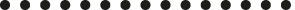

The first continuous press machine

The installation of the first continuous press, a great landmark in industrial terms. Thanks to new technology a great step forward was made in terms of production efficiency, with in particular greater volumes and less wastage of resources, while maintaining quality and uniformity of the product.

-

The Ecological Panel

Mauro envisaged a sustainable future. The objective was to make particleboard panel entirely from recycled wood. It was a pioneering project, received with some scepticism, that involved expenditure of very large investments in research and development. The Ecological Panel was presented to the market, made from materials that were defined as waste and scrap. This was the dawn of the circular economy, the start of a new era, that of the Eco-Ethical Company.

-

The Mauro Saviola Group began

At the end of the nineties, the company conglomerate led by Mauro began to be a group with a capital “G”, as the Mauro Saviola became a de facto group, the Gruppo Mauro Saviola. The acquisition of Nuova Rivart in Radicofani, specialised in the processing of chestnut wood, allows the manufacturing of MDF panels and processing of tannin, essential to the tanning industry. Sitapan and Sitech came into being, and they specialised in manufacturing semi-finished products for furniture, edges and surfaces, making their way into the factories of the main Italian players. Also in 1997, 100% production of Ecological Panels was achieved. From this moment on no tree would ever be felled for the production of a Saviola panel.

-

The LEB panel

In the meantime, work was going on to bring formaldehyde emissions down as far as possible. Out of this came the LEB and the IDROLEB panels, excellently performing products with the lowest emissions on the market. With the advent of the new millennium, the Mauro Saviola Group guaranteed that 100% of its particleboard panel was manufactured using raw materials saved from waste disposal sites. Through a dense network of Ecolegno (wood recycling) centres, the Group collects post-consumer wood in Italy and abroad.

-

Composad: new life for Italian design

The last piece of the jigsaw of vertical and horizontal integration appeared, and with it the closure of the worthy circle of Chemicals, Wood, Furniture. So it was that Composad was established, bringing ready-to-assemble furniture, matching beauty, functionality and sustainable development. In just a few years, the new company earned a primary role in the international panorama of modular furniture.

-

The reins pass to Alessandro

In 2009, at the dawn of the worst economic crisis of the post war period Mauro passed away and the leadership of the group passed to his eldest child Alessandro. In 2011 the strategy taken up to meet the crisis involved the careful reorganisation of the company for leaner resource management, more flexible production process and the cutting of waste.

-

Trendcor: the creative hub in Frankfurt

Attention to design became ever more important. The Group transferred its creative and technical workshop to Frankfurt, in the living heart of Europe, and in particular in the country where its principal competitors were trading, while investing in new specialised figures.

Trendcor was seeking new sources of inspiration and aesthetic details. Here thanks to an original co-creation process initiated with customers, the surfaces to be applied on the panels took form, to finally end up in the home, shops and hotels. -

Embossed in Register

The Group once again brought together design and innovation with the introduction to the market of Embossed in Register, a perfect alignment of decorative design and surface texture achieved through the use of sophisticated electronic and mechanical technology. It is the ecological alternative to real wood. In the meantime the international markets were opening up further, with the start-up of important trading partnerships for Asia.

-

Saviolife was born

Saviolife, a new business unit came into being, dedicated to the life sciences, livestock breeding and nutrition. The objective being to permit, once again, an opportunity for selecting an innovative and sustainable option, in short the Eco-Ethical option.