A mission, our mission, reached together through a culture of “doing” rather than talking.

We are today a real and worthy example of Circular Economy, a case study discussed in Italy and around the world.

These are the guiding principles for taking up the challenges of the future with a passion.

Staying faithful to our story first and foremost means continuing to do business with the greatest respect for the environment through eco-sustainability and a recycling ethic.

Alessandro Saviola – Chairman

Our position

We are believers in a sustainable future

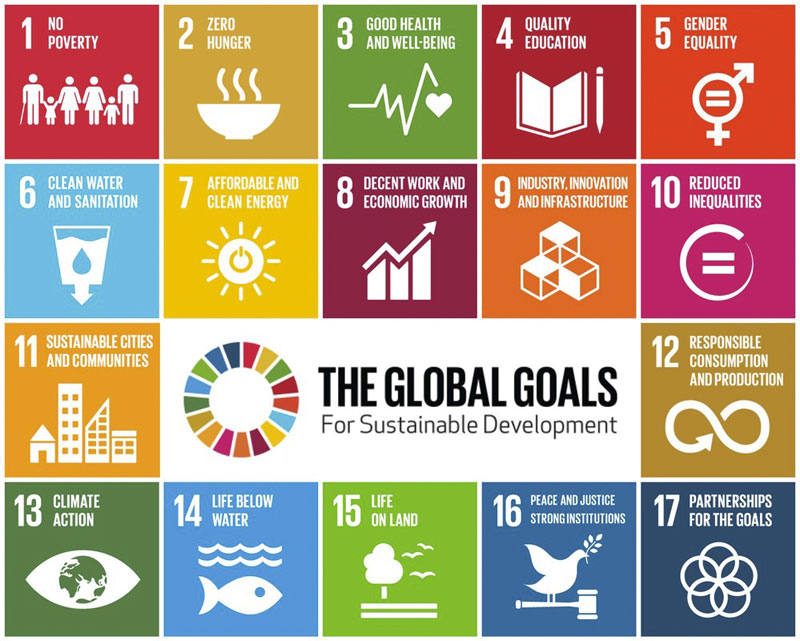

This is a world in transformation. The future of our planet depends on what we do today. According to the recent Intergovernmental Panel on Climate Change (IPCC) report, we only have 12 years to slow global warming.

Our work, on a day-by-day basis, aims to lower CO2 emissions, save on raw materials, recycle and conserve trees. All of us working together can and must play our part: whether as institutions, companies or simply as individuals; we can all get involved in the new challenges dictated by these changes. Only our combined efforts can help reach the UN’s Sustainable Development Goals (SDGs), a beacon to follow in our choices for our future.

Let’s embrace the circular economy

When we began to be involved in the circular economy it was still the nineteen seventies. The notion of the circular economy was invented in those years but it was not until the first decade of the new millennium that this production model began to truly gain traction.

It is only in the last few years that the European Commission has focussed on the subject and has worked out an ambitious package of measures to help European business and consumers to make the transition to the new economy in which resources are utilised in sustainable fashion.

Today many companies are talking about the circular economy, or find that they have no choice but to do so. For us, it is simply in our DNA, and impacts on all company policy, strategies, plans and economic decisions. Planning, production, procurement of resources, product life and end-of-life are all fundamental for Saviola, and are all connected one to another to give life to a truly Eco-Ethical company.

All of this without losing sight of the aesthetic and functional qualities of our products. With the LEB (low emission board) panel we have created the first 100% recycled particleboard with emissions close to those of virgin wood. With the embossed in register process we have faithfully reproduced the characteristic of wood, both visually and to the touch, being the best eco-sustainable alternative in the world. Our Research Centre in Frankfurt and our modular furniture production processes have made the Italian design available to everyone.

Manufacturers are responsible for the whole life cycle

Getting the very most out of the whole life cycle of the product to save on raw materials and reduce emissions must be the objective we all aim for.

We know the value of post-consumption raw materials and actively adhere to European directives with best practice for best development of resources, making waste products the essential raw material in our production of boards.

Every new product will one day become waste and it is the duty of all manufacturers to think of the whole process right through to the conclusion of the cycle. This is the Extended Production Responsibility model that is already being applied now to packaging.

Public and privates need to cooperate

We have always vigorously advocated public and private collaboration to speed the passage to the circular economy.

VWe would like to see our efforts as part of a shared national, European and worldwide commitment to a common objective where industrial symbiosis, raising awareness, exchange of knowledge, incentives and certification become matters of ordinary administration.

We promote the adoption of an ethical minimum emissions standard for particleboard for the whole of Europe (E1). We are firm believers in Green Public Procurement, an instrument that the public institutions have available as a driving force for the market in sustainable production.

Recycling before combustion

In the last few years we have acted as a spokesperson for the important battle to raise public awareness of the campaign “Don’t burn Made in Italy”, on the need to assure the priority for wood recycling as opposed to the burning of its biomass.

Recycling has been acknowledged by a study on the environmental impact of each stage in the respective processes to be the best end of life scenario for wood waste. Eco-incentives for biomass energy production plan has been somewhat paradoxical for us as manufacturers of particleboard panels. Every year 600 thousand tons of wood waste is imported into Italy, a resource which would in reality be one that is in abundance.

Chemicals can be sustainable

In the horizontal integration that characterises us, our chemical business unit works in perfect synergy with the other divisions.

It is in this sector, and in those of the life sciences, that we once again show ourselves to be committed to sustainable industry. A glue with emission close to that of virgin wood, a natural alternative to antibiotics for livestock, a vegetable product for use in the working of skins, and so forth …

In our Group every innovation is only considered to be such if it brings an actual benefit not only to the business logic but also to all that which this involves.